Polyethylene terephthalate

degrading hyrdrolyase enzyme from Ideonella Sakaiensis

Meheret Ourgessa '23 and Beimnet Kassaye '23

Contents:

I. Introduction

Polyethylene terephthalate (PET) is the most abundant type of plastic

in the world. It is used to make single-use bottles, packaging,

containers, and clothing. PET degrades at a very slow rate under

normal conditions, and this property has made it a major pollutant to

both land and water. Chemical recycling is the primary way of

degrading and depolymerizing PET, but the process is not

cost-effective since raw PET is cheaper than its recycled counterpart.

Analysis of PET contaminated matter from a recycling plant led to the

discovery of a bacterial species that uses PET as a carbon source. The

bacterium, Ideonella sakaiensis, secrets the enzyme

polyethylene terephthalate hydrolase (PETase) to hydrolyze the ester

bond in PET and convert it to BHET (Bis(2-hydroxyethyl) terephthalate)

and MHET (Mono-(2-hydroxyethyl)terephthalic acid). The bacteria also

produces MHETase, an enzyme that further breaks down MHET into the

monomers terephthalic acid and ethylene glycol.

While PETase from Ideonella sakaiensis has common

structural and functional properties with other hydrolases (such as

cutinases and lipases), it also has special features that allow it to

act on PET at room temperature. Research on the mechanism of the

enzymatic action is still under study, but it has already led to the

discovery of mutants which degrade PET with higher efficiency.

Figure 1. Scheme of polyethylene terephthalate degradation by PETase

into BHET(Bis(2-hydroxyethyl) terephthalate) and

MHET(Mono-(2-hydroxyethyl)terephthalic acid). MHETase further breaks

down MHET into the monomers TPA(terephthalic acid) and EG(ethylene

glycol).

II. General Structure

A member of the α/β-hydrolase family, PETase has a core containing

eight

and six

in its tertiary structure. The protein adopts an

α/β-hydrolase fold as would be predicted from its sequence homology

with proteins from the cutinase and lipase families. The surface of PETase is

polarized to highly acidic and basic areas with an isoionic point of

9.6. The weight of the protein is 31.46 kDa with a residue count of

265.

Within the active-site, the catalytic triad conserved across

cutinases and lipases is also present in PETase. In this protein,

comprise the catalytic triad. These catalytic residues

reside on loops. The nucleophilic serine residue occupies a highly

conserved position called the nucleophilic/catalytic elbow. This

structure has the consensus sequence (G-X1-S-X2-G). While X1 in

cutinases and lipases is usually occupied with phenylalanine or

histidine, in PETase, the position is occupied by tryptophan

giving the enzyme an extended hydrophobic surface next to

the active site.

Compared to its closest cutinases homologs, PETase has a broader

active-site cleft, and, at its broadest point, approaches three times

the width of the corresponding structure in the Thermobifida fusca

cutinase, another enzyme known for its ability to hydrolyze PET. This broadening happened with minimal rearrangement of

adjacent loops and the secondary structure; only a single amino acid

substitution from phenylalanine to serine (ser160) in the active site

seems to have caused it. The

of PETase is then formed between two tryptophan residues

(Trp159 and Trp185) and the novel Ser160.

PETase has two disulfide bonds, one that is adjacent to the active

site and another one close to the C terminus of the protein. The first

disulfide bond is between

and connects

, stabilizing the whole molecule. PETase's second disulfide

bond,

, is next to the active site and

a hidden site in β-sheet 7, which is found immediately below

the active site, to a loop that connects β-Sheet 8 with α-Helix 5.

This loop has the catalytic histidine His237. The disulfide bond

anchors the loop and stabilizes the histidine and the entire catalytic

triad. This stabilization allows for higher flexibility at room

temperature, which is a property absent in other thermophilic

hydrolases.

III. PET Binding and Degradation Mechanism

IFD (Induced-fit Docking) protocol has been used to predict

PET-PETase binding modes. It is thought that in a productive

PET-binding event, Ser160 is positioned at a distance of 5.1 Å from

the carbonyl carbon of PET. Within the same model, His237, positioned 3.9 Å from

Ser160, would

the serine residue for nucleophilic attack through a hydrogen

bond. Further, Asp206 provides

to His237 from a distance of 2.8 Å.

A

of PETase bound to a ligand, HMET (1-(2-hydroxyethyl)

4-methyl terephthalate), elucidates the exact mechanism of PET

degradation. HMET is a substrate analog here since, like PET, it has

an ester bond moiety and an aryl group. This structure

contains an

to inactivate the enzyme and determine the ligand-bound

structure. PET degradation seems to be achieved by the hydroxyl group

of the activated Ser160 attacking the carbonyl carbon of HEMT (and,

thus, likely PET too) in a nucleophilic acyl substitution mechanism.

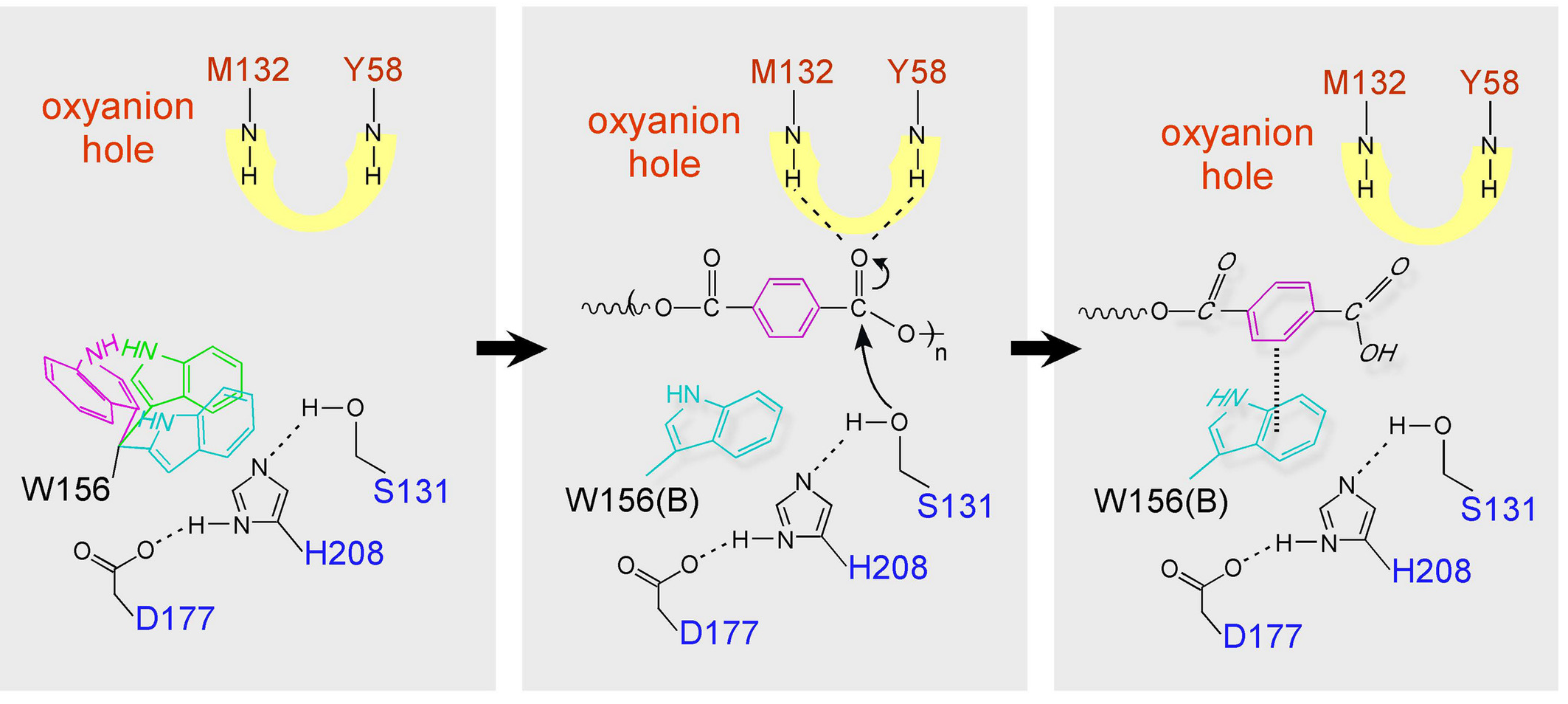

During this attack, the ester group approaches the enzyme with the

carbonyl oxygen facing the

formed by Tyr87 and Met161

(Figure 2). These residues are both within

of the carbonyl carbon being attacked in HMET. The

positively charged nitrogen atoms in the oxyanion hole can stabilize

the partial negative charge on the carbonyl oxygen of the ester.

Leu208 and Met161 further provide

to HMET.

, a part of the active-site cleft, rotates as PET is bound in order to form aromatic

interactions with the molecule. The reorientation of Trp185 in the

ligand-bound model of PETase also suggests that the movement of this

residue opens up the active-site of the enzyme. Additionally,

seems to allow this rotation or wobbling of Trp185 and is therefore an

important feature of PETase.

After the first nucleophilic attack by the activated Ser160, a water

molecule will complete the cleavage of the ester bond (now between

Ser160 and the substrate) which leads to the formation of tereaphtalic acid.

The aromatic portion of the

terephthalic acid moiety then strengthens its hydrophobic interactions

(base stacking) with the indole ring in Trp185. This base stacking

will induce an angular change to the conformation of the substrate

initiating product release (Figure 2).

Figure 2. Binding and degradation of the analogous substrate HMET by

PETase. Interactions with the protein during product release are also

shown. All amino acid position numbers in this figure are shifted down

by 29 (for example, Y58 is the same as the residue Tyr87 presented in

the text).

IV. Improving Degradation

Specific mutations to the amino acids of PETase enhance degradation.

A double mutant with S238F/W159H outperforms the wild type at

degrading PET that has higher crystallinity like the one found in

plastic bottles. Like cutinases, the mutant had a narrower active site

that gave it better crystallinity reduction and product release. The

S238F mutation introduced a ring that allows for more hydrophobic

interactions with the surrounding terephthalate, and the W159H

substitution reduced steric hindrance and deepened the space in the

active site for PET binding.

Another substitution L117F was made at a position outside of the

active site channel. The change from the aliphatic to the

aromatic phenylalanine allowed for faster PET binding and release of

products. This mutant also outperformed the wild type PETase; its

degradation rate was 2.1 times that of the wild type. Mutation of

, found close to the active site, to the ringed phenylalanine gave

better PET binding, and the rate of degradation increased by 2.5

folds. The aromaticity of phenylalanine enhances degradation because

ring stacking between the amino acid residue and terephthalate

increases binding of the enzyme to PET.

The improved degradation by these protein-engineered mutants is

evidence that the activity of PETase could be enhanced and more PET

could be recycled faster.

V. References

Austin, H. P., Allen, M. D., Donohoe, B. S., Rorrer, N.

A., Kearns, F. L., Silveira, R. L., � Beckham, G. T. (2018).

Characterization and engineering of a plastic-degrading aromatic

polyesterase. Proceedings of the National Academy of Sciences,

115(19). https://doi.org/10.1073/pnas.1718804115

Chen, C. C., Han, X., Ko, T. P., Liu, W., & Guo,

R. T. (2018). Structural studies reveal the molecular mechanism of

PETase. The FEBS Journal , 285(20), 3717�3723.

https://doi.org/10.1111/febs.14612

Fecker, T., Galaz-Davison, P., Engelberger, F.,

Narui, Y., Sotomayor, M., Parra, L. P., & Ram�rez-Sarmiento, C.

A. (2018). Active Site Flexibility as a Hallmark for Efficient PET

Degradation by I. sakaiensis PETase. Biophysical Journal ,

114(6), 1302�1312. https://doi.org/10.1016/j.bpj.2018.02.005.

Ma, Y., Yao, M., Li, B., Ding, M., He, B., Chen, S.,

� Yuan, Y. (2018). Enhanced Poly(ethylene terephthalate) Hydrolase

Activity by Protein Engineering. Engineering, 4(6),

888�893. https://doi.org/10.1016/j.eng.2018.09.007

Zhou, Yuhong, Ziaoping Zhang, and Richard H. Ebright.

1993. Identification of the activating region of catabolite gene

activator protein (CAP): Isolation and characterization of mutants

of CAP specifically defective in transcription activation. Proceedings

of the National Academy of Sciences of the United States of

America 90:6081-6085.

Back to Top